Technology Development Center

Recently, social demand for more sophisticated product performance is very high, such as further reduction of noise & vibration on various machineries and devices, development of hybrid vehicle, energy saving and environmental protection measures for automobile, etc. In this regard, more highly accurate test and measurement are badly required in the forefront of product development.

The capability of ESTECH test laboratories meets the client demand by executing very reliable test and measurement to provide high accuracy and quality data.

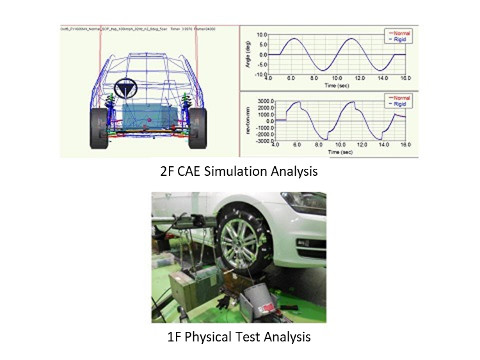

In order to further increase the value of test-driven CAE, both test analysis experts and CAE analysis experts work hard together while sharing information in the same premise, and this is a hub to develop technologies that are truly useful for designing and manufacturing products.

Features of the Technology Development Center

1: Improving the quality of engineering service and engineering resource development

Vibration and noise test areas are located on the 1st floor in the Technology Development Center, and computer analysis servers and an office for engineers to perform test data analysis as well as CAE simulation analysis are on the 2nd floor.

Test analysis experts and CAE analysis experts work together to solve the engineering problem of client while sharing information and knowledge in the same premise, and they promote advanced proprietary CAE technologies to contribute to client's' product design and development works.

In order to promote test driven CAE, engineers are fostered, who have both test analysis technology and CAE simulation analysis technology.

2: Test infrastructure enhancement

2-1: Dividable test area with large surface plates

The vibration and noise test areas are newly built in the 1st floor, and dividable into 3 to 5 sections. All sections are equipped with a large embedded vibration free surface plate suspended by independent foundation from the floor of room that makes it possible to measure highly accurate vibration data, and a quite simple anechoic chamber structure with sound-absorbing material placing surrounding walls and ceiling.

The central three sections are test spaces which can be used flexibly by connecting each other without partition wall.

The followings are further description of facilities mentioned above.

- Large surface plate: 5 set

Floor embedded 4.5m x 3m size large surface plate with T-slot is placed respectively.

Highly accurate vibration test environment is created by cutting off the background vibration using an independent foundation of a concrete block with a thickness of 1m or more to vibrationally isolate the surface plate from the general floor.

- Test room:5

6m wide x 12m long x 5m high/each room.

The two rooms are completely partitioned by walls

These rooms are especially for test of highly confidential products and/or test project that clients stay and work at the center over a prolonged period.

By connecting the other three rooms into a large hall, a highly flexible test layout is available (18m wide x 12m long x 5m high))

In addition to the above mentioned new equipment of the Technology Development Center, original unique test technologies of ESTECH can be provided to clients by combining the following test equipment which ESTECH have been using from the past.

-

Front-end: approx. 800 channels

-

Accelerometer: approx. 850 sets

-

Microphone: approx. 90 sets

-

Electromagnetic Exciter: 18 sets

-

Impact Hammer: 26 sets

-

Sound Source Probe Acoustic Camera: 1 set

Combined test facilities of the Technology Development Center with those of the existing test site, the test capability has more than doubled which makes it possible to conduct test work in an environment and schedule that meet client's needs.

3: New hydraulic vibration test room with a work pit

A hydraulic vibration exciter is installed in the test room, which enables the company to conduct a test of minute deformation of such as a vehicle body in the driving comfort and steering stability research areas. These phenomena are impossible to clarify with electromagnetic exciter.

Features of the test with a hydraulic vibration exciter

- Compact and versatile excitation head makes it possible to conduct test with flexible layout

- Random vibration, sweep sign vibration, compound vibration, and PSD vibration tests under operating condition are workable

-

The most frequent applications

- Dynamic spring characteristics measurement of rubber parts such as bushes, and a vehicle body hysteresis measurement

- Test for road noise analysis with a vehicle ground contact surface excitation

- Vibration fatigue test of parts

- Seismic test of an electronic equipment

ESTECH keeps striving to meet the client’s needs in the manufacturing industry that are becoming more complex and sophisticated by making full use of newly established Technology Development Center and further advancing analysis technologies as well as expanding and upgrading test technologies.

Facilities

Hemi-anechoic room

- The room meets JIS standard with the usable dimensions of W6.5 m X L8.5 m X H4.4 m. The 4 walls and ceiling are covered by 0.5 m length of sphenic shape noise absorber, where 4.5 m X 2.5 m iron bed is installed as well as an engine noise measurement of even a big truck cabin can be taken place with exhauster.

Excitation Room

- The room is arbitrarily divided by partition walls, where two iron beds and a 2.8 t overhead travelling crane are installed. The height of the room is 7.0 m, which enables test engineer to conduct excitation test for over size test specimen. All test rigs and instruments are placed in the racks built in walls not to disturb noise measurement in the room.

- All walls and a ceiling are covered with 50mm glass wool.

- Hydraulic vibration test room with a work pit.

- Independent vibration test room.

Vehicle test preparation room

- A set of Hydraulic car lifter without poles and a 2.8 t overhead travelling crane are installed. The room height of 7.0 m is good for workability. Vehicles for the test can be carried in the room with carrier truck for keeping confidentiality.