FE Model development

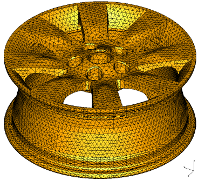

The reverse engineering is applied to develop high-accuracy FE models which road wheel modeling is shown as an example.

Summary

In the case of large casting product, discrepancies are often observed between CAD geometry and real one due to the presence or absence of draft angle, therefore, CAE model created from CAD is hard to correlate to the real product. Under reverse engineering technique, 3D measurement of the real product makes it possible to develop highly accurate FE model which can be well correlated to the real one.

Additionally, it is important for the modeling method development to identify the location information on the structure to obtain the correlation of the model by comparing reverse engineering model with the one created from CAD.

If the simulation for a product of the competition is required, the CAE model is able to be created by utilizing measured geometry of the product applying reverse engineering technique.

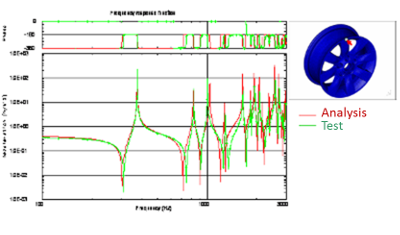

The company possesses capability to develop highly accurate 3D CAE model using own 3D geometry measuring equipment which applies to the real product to develop FE model and meshes, and the accuracy of the model is verified by physical test such as artificial excitation test.

Vehicle road wheel FE model developed by reverse engineering